Precision and Efficiency: The Hallmarks of CNC Metal Machining

CNC, which stands for Computer Numerical Control, is a technology that uses computers to control machine tools. In the context of metal machining, this means that high-precision components can be produced with remarkable accuracy. The process involves a series of programmed instructions that guide the machine's cutting tools, ensuring that each part is manufactured to exact specifications.

Industry Applications of CNC Metal Machining

The versatility of CNC metal machining is evident in its wide range of applications:

Aerospace: In this industry, where safety and reliability are paramount, CNC metal machining is used to produce complex and precise components such as engine parts, landing gear, and aircraft structures.

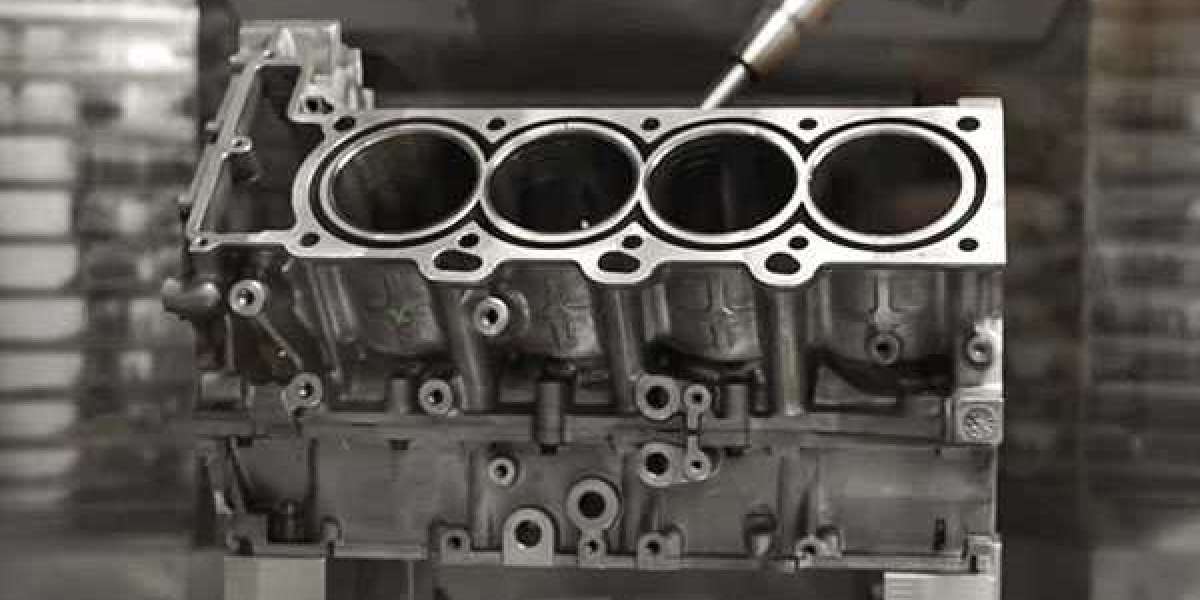

Automotive: The automotive sector relies heavily on CNC metal machining for the production of engine components, transmission systems, and chassis parts. The technology allows for the creation of lightweight yet strong parts that contribute to fuel efficiency and performance.

Medical Devices: Precision is crucial in the medical field, and CNC metal machining plays a vital role in the production of surgical instruments, prosthetics, and implantable devices.

Defense and Security: For the defense industry, CNC metal machining is essential for the production of high-precision weapons, ammunition, and vehicle components that must withstand extreme conditions.

Energy: In the energy sector, CNC metal machining is used to manufacture components for wind turbines, solar panels, and nuclear reactors, where durability and precision are key.

The Importance of CNC Metal Machining in Industry

The importance of CNC metal machining in modern industry cannot be overstated:

Quality and Consistency: CNC machines ensure that each part produced is identical to the next, which is critical for maintaining quality standards and consistency across products.

Cost-Effectiveness: By automating the machining process, CNC technology reduces labor costs and minimizes material waste, making it a cost-effective solution for high-volume production.

Shorter Lead Times: The efficiency of CNC metal machining allows for faster production times, which is particularly beneficial for industries with rapidly changing demands.

Customization and Flexibility: CNC machines can be programmed to produce a wide variety of parts, making them ideal for custom and prototype production.

Sustainability: With the ability to use materials efficiently and produce fewer waste products, CNC metal machining contributes to more sustainable manufacturing practices.

The Future of CNC Metal Machining

As technology continues to advance, so does the capability of CNC metal machining. With the integration of artificial intelligence and advanced materials, the future of CNC metal machining promises even greater precision, efficiency, and innovation.

Conclusion

CNC metal machining is a cornerstone of modern industry, driving innovation and precision in manufacturing. Its impact on various sectors, from aerospace to medical devices, is undeniable. For more information on how CNC metal machining is shaping the future of production, visit CNCLathing's CNC Metal Machining page. Discover the cutting-edge technology that is propelling industry forward and the precision that defines modern manufacturing.