When it comes to precision metalworking, selecting the right punch tool is crucial for achieving optimal results. TRUMPF punches are renowned for their quality, efficiency, and versatility in various manufacturing applications. In this guide, we will explore how to choose the right TRUMPF punch for your specific needs, highlighting key features and considerations to ensure you make an informed decision. This article will also showcase the offerings from AE Tooling, a trusted provider of TRUMPF tools.

Understanding TRUMPF Punches

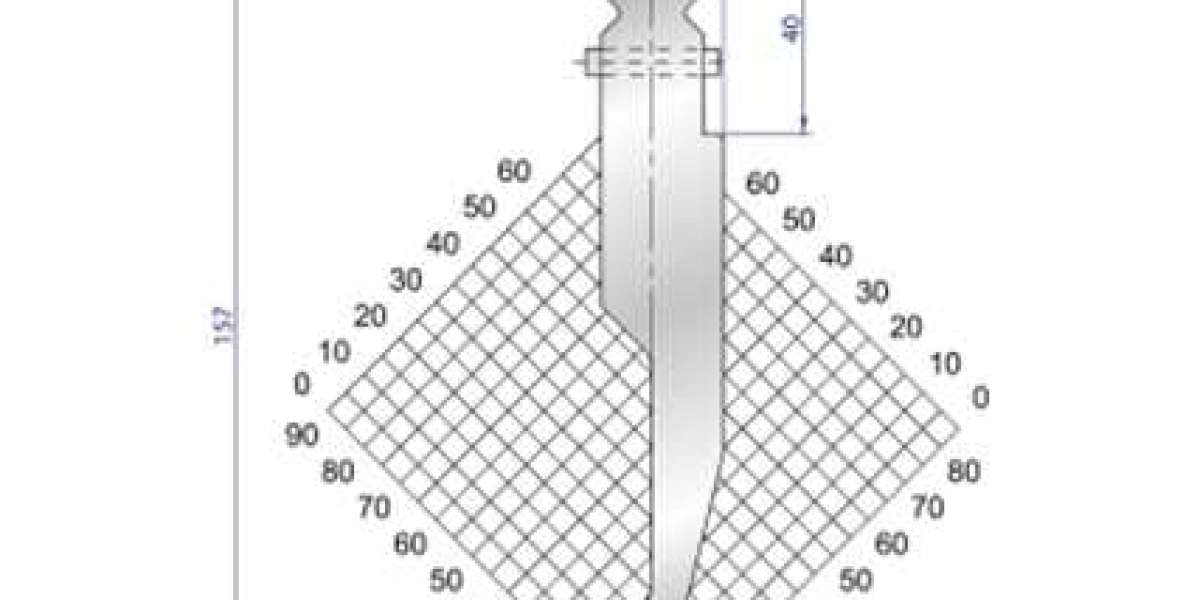

TRUMPF punches are designed for use with punching machines, allowing manufacturers to create precise holes and shapes in sheet metal. These tools come in various types, angles, and sizes, making them suitable for a wide range of applications—from simple perforations to complex geometries.

Key Features of TRUMPF Punches

1. Material Quality: Most TRUMPF punches are made from high-quality tempered steel, such as 42CrMo, which ensures durability and longevity. This material choice allows the punches to withstand the rigors of industrial use while maintaining sharpness.

2. Variety of Angles and Radii: TRUMPF offers punches with different angles (e.g., 60°, 80°, 86°, etc.) and radii (e.g., R0.5, R0.8, R1). This variety enables manufacturers to select the perfect punch for their specific design requirements.

3. Custom Lengths: TRUMPF punches come in a range of lengths (e.g., 25mm to over 3000mm), providing flexibility for different applications and ensuring compatibility with various punching machines.

4. Compatibility: TRUMPF punches are designed to work seamlessly with TRUMPF punching machines like the TruPunch series, ensuring optimal performance and efficiency.

Factors to Consider When Choosing a TRUMPF Punch

1. Application Requirements

Before selecting a punch, consider the specific application you need it for. Are you working with thin sheet metal or thicker materials? Do you require simple holes or complex shapes? Understanding your application will help you determine the appropriate angle, radius, and size of the punch.

2. Material Type

Different materials may require different punching tools. For instance, softer materials like aluminum may not require as robust a punch as harder materials like stainless steel. Ensure that the punch you choose is suitable for the material you will be working with.

3. Punch Angle and Radius

The angle and radius of the punch significantly affect the quality of the punched hole and the overall design aesthetics. For example:

- 60° Punches: Ideal for creating sharp angles in sheet metal.

- 80° Punches: Versatile for general applications where moderate angles are required.

- 86° Punches: Suitable for applications requiring more acute angles.

Choosing the right angle will enhance both functionality and appearance in your final product.

4. Length Considerations

The length of the punch should correspond with your machine's specifications and the thickness of the material being processed. Ensure that the punch length is compatible with your punching machine setup to avoid any operational issues.

5. Cost Efficiency

While investing in high-quality punches may seem costly upfront, consider their longevity and performance capabilities. High-quality TRUMPF punches can lead to fewer replacements and repairs over time, ultimately saving costs in your manufacturing process.

AE Tooling: Your Trusted Partner for TRUMPF Punches

At AE Tooling, we specialize in providing high-quality TRUMPF punches tailored to meet diverse manufacturing needs. Our extensive range includes various angles, radii, and lengths to ensure that you find the perfect tool for your specific application.

Why Choose AE Tooling?

- Expert Guidance: Our knowledgeable team is here to help you identify the best punch tools based on your unique requirements.

- Quality Assurance: We offer only genuine TRUMPF products that adhere to stringent quality standards.

- Competitive Pricing: Our pricing structure is designed to provide value without compromising on quality.

- Comprehensive Support: We provide ongoing support and resources to ensure that your operations run smoothly.

Conclusion

Choosing the right TRUMPF punch is essential for achieving precision and efficiency in your manufacturing processes. By considering factors such as application requirements, material type, punch angle and radius, length considerations, and cost efficiency, you can make an informed decision that enhances your production capabilities.

With a trusted partner like AE Tooling, you can access a wide range of high-quality TRUMPF punches tailored to meet your specific needs. For more information about our products or assistance in selecting the perfect punch for your operations, please contact us today! Let us help you elevate your manufacturing processes with our exceptional tooling solutions!