Wood processing is a complex and intricate industry that requires precision and efficiency to produce high-quality products. One crucial component in wood processing is the hot platen, which plays a significant role in various stages of the manufacturing process. In this blog, we will explore the application of hot platen in wood processing, its benefits, and how it enhances the overall production efficiency.

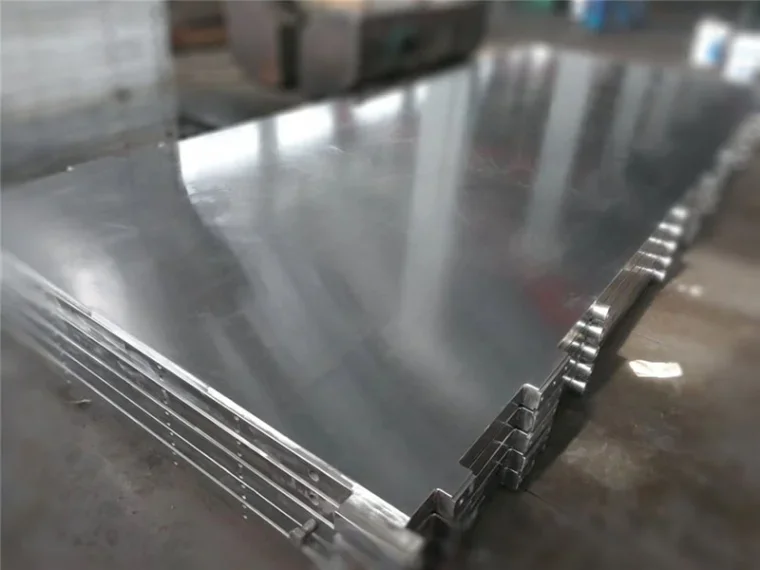

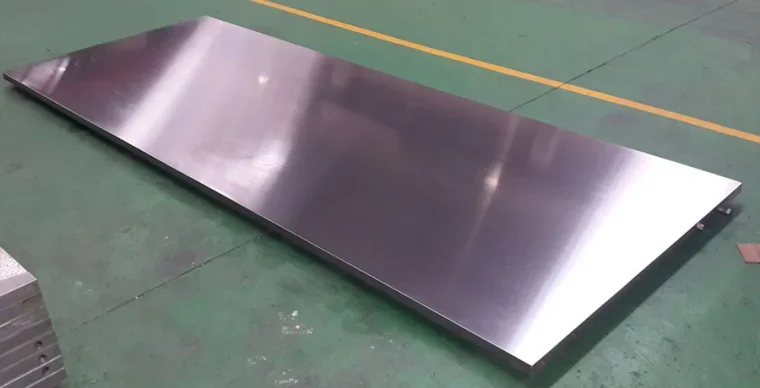

I. What is a Hot Platen?

A https://www.nuknail.com/Hot-Platen, also known as a heated press plate, is a flat surface made of metal, typically steel, that is heated to high temperatures. It is an essential component in various wood processing machines, such as wood drying kilns, presses, laminators, veneer production lines, and edge banding machines. The hot platen is designed to provide uniform heat distribution and pressure to the wood material, facilitating specific processes in wood processing.

A. Function:

The hot platen serves two primary functions in wood processing. Firstly, it provides heat to facilitate the drying, pressing, lamination, bending, and forming of wood materials. Secondly, it applies pressure to ensure proper adhesion, bonding, and shaping of the wood.

B. Types of Hot Platens:

There are different types of hot platens used in wood processing, depending on the specific application and machinery. Common types include solid hot platens, drilled hot platens, and grooved hot platens. Solid hot platens provide a smooth and even surface for processes like wood drying and pressing. Drilled hot platens have holes drilled into them to allow for the circulation of steam or hot air during wood drying. Grooved hot platens have grooves or channels that help distribute heat and pressure evenly during processes like veneer production.

II. Hot Platen in Wood Drying Process

A. Importance of Wood Drying:

Wood drying is a critical process in wood processing as it reduces the moisture content of the wood, making it more stable and suitable for further manufacturing. Properly dried wood minimizes the risk of warping, cracking, and other defects.

B. Role of Hot Platen in Wood Drying:

https://www.nuknail.com/Hot-Platen are used in wood drying kilns to provide the necessary heat for moisture evaporation. The hot platen ensures uniform heat distribution across the wood surface, promoting efficient and consistent drying. It helps to remove moisture from the wood fibers, reducing the drying time and improving the overall quality of the dried wood.

C. Benefits of Using Hot Platen in Wood Drying:

1. Faster Drying: The application of heat through the hot platen accelerates the drying process, reducing the overall drying time required.

2. Improved Quality: The uniform heat distribution provided by the hot platen ensures that the wood dries evenly, minimizing the risk of defects such as warping or cracking.

3. Energy Efficiency: Hot platens are designed to provide efficient heat transfer, optimizing energy consumption during the wood drying process.

4. Increased Productivity: With faster drying times, wood processing companies can increase their production output, meeting customer demands more efficiently.

III. Hot Platen in Wood Pressing and Lamination

A. Wood Pressing Techniques:

Wood pressing involves applying pressure and heat to bond multiple layers of wood together, creating composite wood products such as plywood or laminated boards. Various pressing techniques, such as cold pressing, hot pressing, and continuous pressing, are used in wood processing.

B. Role of Hot Platen in Wood Pressing and Lamination:

Hot platens play a crucial role in wood pressing and lamination processes by providing the necessary heat and pressure. During hot pressing, the hot platen ensures that the adhesive used between the wood layers cures properly, resulting in a strong and durable bond. It also helps in shaping and forming the wood material to the desired dimensions.

C. Benefits of Using Hot Platen in Wood Pressing and Lamination:

1. Enhanced Bonding: The application of heat and pressure through the hot platen ensures a strong and reliable bond between the wood layers, improving the overall quality and durability of the final product.

2. Efficient Curing: The hot platen facilitates the proper curing of adhesives, ensuring optimal bonding strength and reducing the risk of delamination.

3. Customization and Shaping: Hot platens allow for the shaping and forming of wood materials during pressing and lamination, enabling the production of intricate designs and customized products.

IV. Hot Platen in Veneer Production

A. Veneer Production Process:

Veneer production involves slicing or peeling thin layers of wood from a log or timber. These thin wood layers, known as veneers, are used to enhance the appearance of furniture, cabinetry, and other wood products.

B. Role of Hot Platen in Veneer Production:

Hot platens are used in veneer production lines to ensure proper bonding and flattening of the veneers. The hot platen applies heat and pressure to the veneers, activating the adhesive and creating a strong bond between the veneer and the substrate.

C. Benefits of Using Hot Platen in Veneer Production:

1. Improved Adhesion: The hot platen ensures that the adhesive used in veneer production cures properly, resulting in a strong and long-lasting bond between the veneer and the substrate.

2. Flattening and Smoothing: The hot platen helps flatten and smooth the veneers, eliminating any imperfections or irregularities, and enhancing the overall appearance of the final product.

3. Increased Efficiency: Hot platens enable faster production cycles in veneer production, allowing manufacturers to meet customer demands more efficiently.

V. Hot Platen in Wood Bending and Forming

A. Wood Bending Techniques:

Wood bending involves manipulating wood materials to achieve curved or shaped designs. Steam bending and hot pipe bending are common techniques used in wood processing.B. Role of Hot Platen in Wood Bending and Forming:

Hot platens are used in wood bending processes to provide the necessary heat to make the wood pliable and easily bendable. The hot platen ensures that the wood reaches the required temperature for bending without compromising its structural integrity.

C. Benefits of Using Hot Platen in Wood Bending and Forming:

1. Enhanced Flexibility: The application of heat through the hot platen makes the wood more flexible, allowing for easier bending and shaping.

2. Consistent Results: Hot platens provide uniform heat distribution, ensuring that the wood bends evenly and consistently, resulting in high-quality finished products.

3. Reduced Risk of Damage: The controlled heat provided by the hot platen minimizes the risk of wood cracking or breaking during the bending process.

VI. Hot Platen in Edge Banding

A. Edge Banding Process:

Edge banding is the process of applying a thin strip of material, known as edge banding, to the exposed edges of wood panels or boards. This process enhances the appearance, durability, and protection of the wood product.

B. Role of Hot Platen in Edge Banding:

Hot platens are used in edge banding machines to activate the adhesive on the edge banding material. The hot platen applies heat and pressure to ensure proper adhesion between the edge banding and the wood surface.

C. Benefits of Using Hot Platen in Edge Banding:

1. Strong Adhesion: The hot platen ensures that the adhesive on the edge banding material cures properly, resulting in a strong and durable bond with the wood surface.

2. Efficient Application: Hot platens facilitate faster and more efficient edge banding processes, increasing productivity and reducing production time.

3. Improved Aesthetics: The hot platen helps in achieving a seamless and smooth edge banding finish, enhancing the overall appearance of the wood product.

Conclusion

Hot platens are indispensable in the wood processing industry, offering numerous benefits and enhancing the overall production efficiency. From wood drying to pressing, lamination, veneer production, wood bending, forming, and edge banding, hot platens play a crucial role in each stage of the manufacturing process.

Liankun was founded in 2006, focusing on the production and research of hot platens for hydraulic press. With "thermal conductive steel platens" as the core product, we have formed five series of products (hot press platens, cold press platens, electric heating platens, mold plates, non-standard plates) and targeted solutions for different industries, scales, and applications worldwide. Liankun is a globally influential hot platen supplier.

Welcome to inquiry if you need to know more about product details or order wholesale.

E-mail:[email protected]

The Application of Hot Platen in Wood Processing