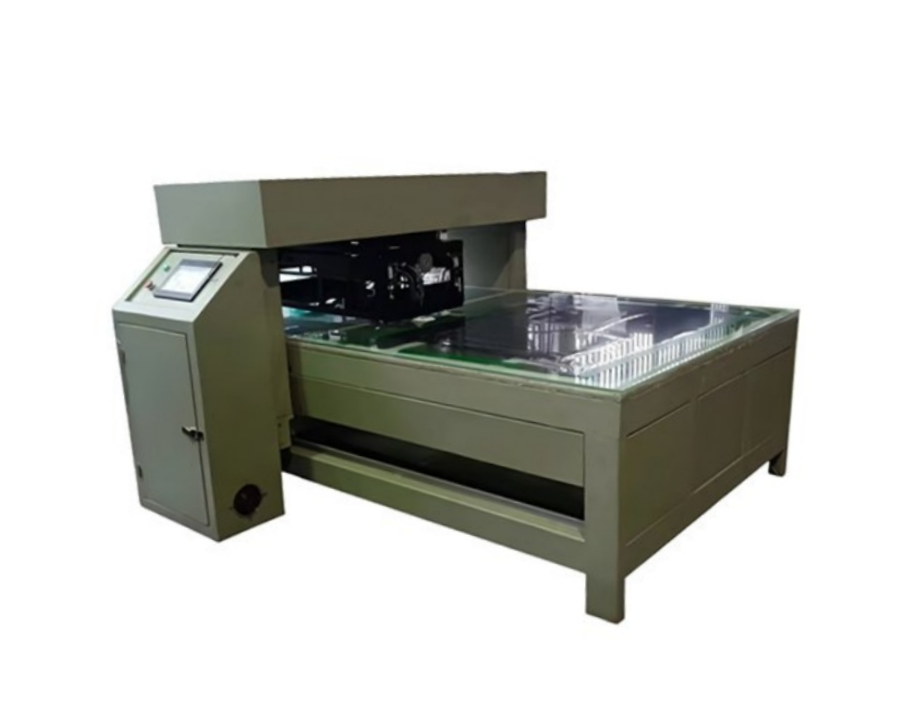

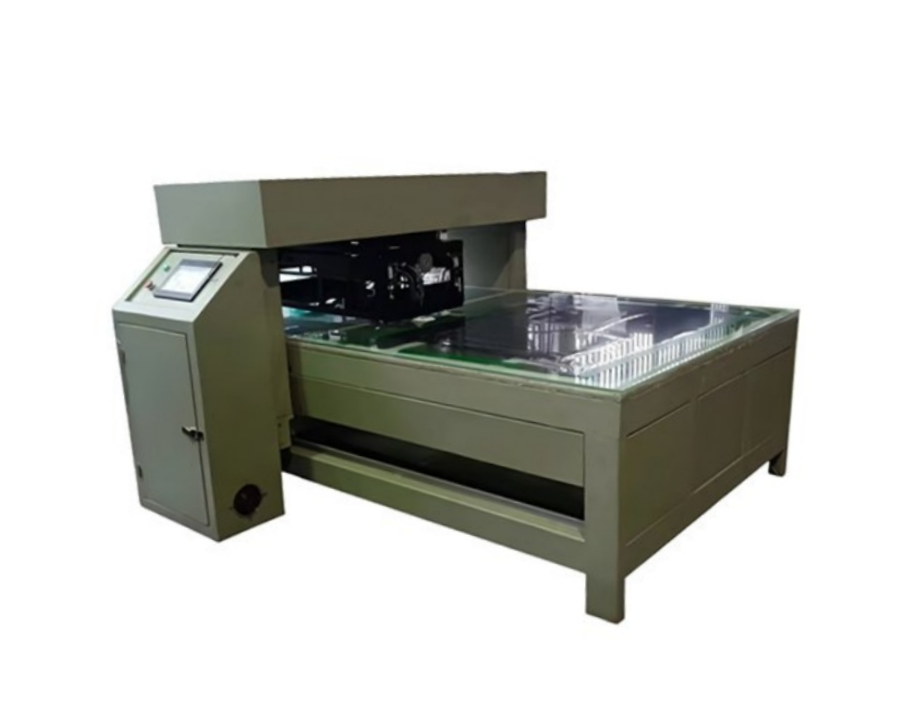

UV recombine machines are innovative tools that have found a wide range of industrial applications across various sectors. These machines utilize ultraviolet (UV) light technology to achieve recombination processes with precision and efficiency. In this article, we will delve into the industrial applications of UV recombine machines

I. Understanding the Technology Behind UV Recombine Machines

https://www.zhhologram.com/UV-recombine-machine.html are equipment used for the recombination of materials through the application of UV light. These machines consist of UV lamps, conveyor belts, cooling systems, and control panels to facilitate the recombination process. The UV light emitted by these machines triggers photochemical reactions, leading to the bonding of materials at a molecular level.

II. Applications in Printing and Packaging Industry

One of the primary industrial applications of UV recombine machines is in the printing and packaging sector. These machines are used to cure UV inks, coatings, and adhesives on various substrates, resulting in quick drying times and enhanced print quality. UV recombine machines enable high-speed production, improved adhesion, and resistance to abrasion, making them indispensable in the printing and packaging industry.

III. Utilization in Electronics Manufacturing

In the electronics manufacturing industry, UV recombine machines play a crucial role in bonding and encapsulating electronic components. These machines provide a reliable method for curing UV-sensitive materials used in circuit board assembly, wire bonding, and chip encapsulation processes. The precise control of UV exposure offered by recombine machines ensures consistent and uniform results in electronics manufacturing.

IV. Application in Automotive and Aerospace Industries

UV recombine machines find applications in the automotive and aerospace sectors for various processes, including bonding, sealing, and coating applications. These machines are utilized for curing UV-resistant paints, adhesives, and sealants in automotive bodywork, as well as for composite bonding and surface treatment in aerospace manufacturing. The efficiency and accuracy of UV recombine machines contribute to the quality and durability of components in these industries.

V. Role in Medical Device Manufacturing

In the medical device manufacturing sector, UV recombine machines are employed for sterilization, bonding, and assembly processes. These machines ensure the effective sterilization of medical instruments and equipment through UV irradiation, eliminating harmful pathogens and ensuring product safety. UV recombine machines also facilitate the bonding of medical components and the assembly of devices with precision and reliability.

VI. Applications in Food and Beverage Packaging

UV recombine machines are utilized in the food and beverage packaging industry for sterilization, labeling, and packaging processes. These machines help maintain the quality and safety of packaged food products by sterilizing packaging materials and labels using UV light. UV recombine machines also aid in the curing of inks and coatings on packaging materials, enhancing product presentation and shelf appeal.

VII. Conclusion

In conclusion, UV recombine machines have become indispensable tools in various industrial applications, offering efficient and effective solutions for material recombination processes. From printing and packaging to electronics manufacturing, automotive, aerospace, medical device manufacturing, and food packaging, the versatility of UV recombine machines is evident across diverse sectors. As technology continues to advance, UV recombine machines will play a key role in enhancing productivity, quality, and sustainability in industrial processes.

UV Recombine Machines: A Sustainable Solution for Eco-Friendly Printing