PP corrugated sheets have gained widespread popularity for their lightweight, durable, and versatile properties. These sheets, made from polypropylene, are used across various industries, from packaging and construction to advertising and agriculture. Their adaptability and cost-effectiveness make them a go-to choice for numerous applications.

What Are PP Corrugated Sheets?

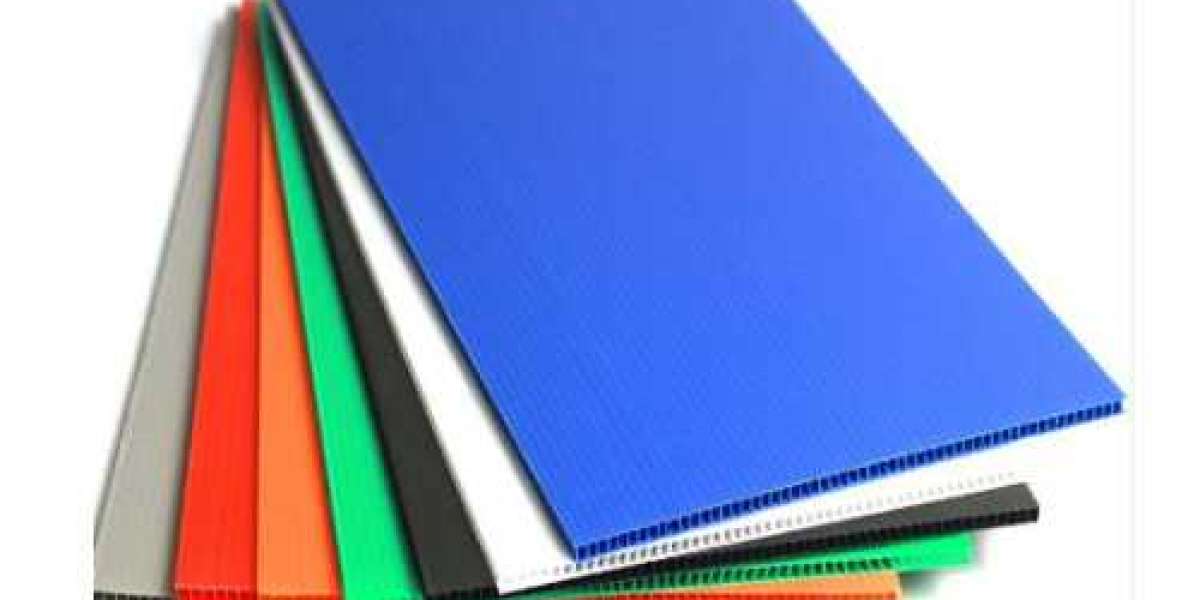

PP corrugated sheets are twin-wall or multi-wall plastic sheets made from polypropylene, a type of thermoplastic polymer. They are characterized by their unique structure, which consists of two flat surfaces separated by a series of parallel ridges or flutes.

This design gives the sheets excellent strength-to-weight ratios, making them durable yet lightweight. The properties of Corrugated PP sheet materials include chemical resistance, water resistance, and recyclability, making them an environmentally friendly option.

Applications of PP Corrugated Sheets

PP corrugated sheets are incredibly versatile, serving a wide range of purposes:

- Packaging: These sheets are widely used in the packaging industry for creating boxes, containers, and protective separators. Their durability ensures that goods remain safe during transit.

- Construction: Builders use PP corrugated sheets as temporary floor protectors, formwork, and signage. Their lightweight nature makes them easy to handle on construction sites.

- Advertising: Printed Corrugated PP sheets are ideal for making signs, banners, and promotional materials. Their smooth surface ensures high-quality print results.

- Agriculture: In agriculture, these sheets serve as protective covers for plants and greenhouses, ensuring controlled environments for better yields.

Features of PP Corrugated Sheets

The design and material properties of PP corrugated sheets offer a host of benefits:

- Lightweight and Durable: The structure of these sheets allows them to be strong without adding unnecessary weight.

- Waterproof and Chemical Resistant: These sheets are resistant to moisture and most chemicals, making them suitable for outdoor and industrial use.

- Customizable: Available in various colors, sizes, and thicknesses, PP corrugated sheets can be tailored to specific applications.

- Eco-Friendly: The sheets are recyclable, aligning with global sustainability goals.

Benefits of Using PP Corrugated Sheets

The benefits of corrugated PP sheets make them a popular choice across industries:

- Cost-Effective: Compared to traditional materials like wood or metal, PP corrugated sheets are more affordable and easier to transport.

- Durability: Their resistance to wear and tear ensures a long lifespan even in harsh conditions.

- Versatility: These sheets can be cut, bent, or shaped to meet diverse requirements.

- Ease of Handling: Their lightweight nature makes them easy to carry, install, and store.

Manufacturing of PP Corrugated Sheets

PP corrugated sheets are produced through an extrusion process, where molten polypropylene is passed through a die to create the corrugated structure. Advanced machinery ensures precise dimensions and uniform quality.

After extrusion, the sheets may undergo additional processes such as UV treatment or flame retardant coating, depending on their intended use.

Choosing the Right PP Corrugated Sheet

When selecting PP corrugated sheets, it is essential to consider factors such as thickness, color, and specific characteristics like UV resistance. The choice depends on the application, whether it's for packaging, construction, or advertising.

Collaborating with trusted Corrugated PP sheet suppliers ensures access to high-quality materials that meet industry standards.

Innovations in PP Corrugated Sheets

With technological advancements, PP corrugated sheets are becoming more efficient and eco-friendly. Innovations include biodegradable options and sheets with improved fire resistance for safer applications.

Printed sheets with advanced ink retention capabilities are being developed for high-impact advertising and branding. These innovations continue to expand the scope of PP corrugated sheets across industries.

Environmental Impact and Sustainability

One of the standout advantages of PP corrugated sheets is their recyclability. After their useful life, the sheets can be melted down and reprocessed into new products, reducing waste and conserving resources.

Manufacturers are increasingly adopting eco-friendly practices, ensuring that the production of these sheets has a minimal carbon footprint.

The Growing Demand for PP Corrugated Sheets

The global demand for PP corrugated sheets is on the rise, driven by their utility in packaging, construction, and advertising. Businesses are recognizing the value of investing in durable and versatile materials to meet their operational needs.

Reputed corrugated PP sheet suppliers are meeting this demand with innovative solutions that cater to diverse industries.

Conclusion

PP corrugated sheets are a practical and cost-effective solution for a variety of applications. Their durability, versatility, and eco-friendliness make them a preferred choice across sectors.

By choosing high-quality PP corrugated sheets, businesses can enhance their operational efficiency while contributing to sustainability goals. As technology continues to evolve, the potential uses for these sheets will only expand, cementing their place as a valuable material in modern industry.

Frequently Asked Questions

What are the main uses of PP corrugated sheets?

PP corrugated sheets are used in packaging, construction, advertising, and agriculture due to their durability and versatility.Are PP corrugated sheets environmentally friendly?

Yes, these sheets are recyclable, making them an eco-friendly choice for various applications.How can I choose the right PP corrugated sheet?

Consider factors like thickness, color, and application requirements, and consult with a reliable supplier for the best options.