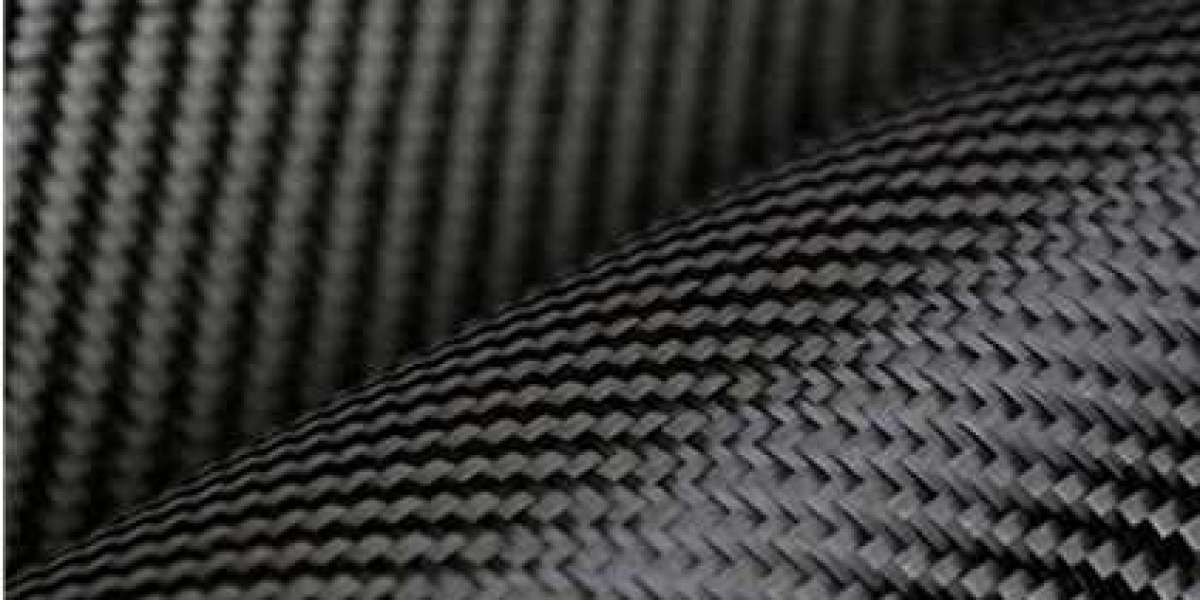

Definition

Carbon fiber is a high-strength and high-modulus fiber with a carbon content of more than 90%, which is produced by high-temperature carbonization of raw materials such as acrylic fiber and viscose fiber.

Characteristic

Carbon fiber has excellent properties such as light weight, high strength, high modulus, high temperature resistance, and corrosion resistance, and is an ideal reinforcement for manufacturing high-performance composite materials.

Raw Material Selection and Preprocessing

Raw materials

Acrylic fiber and Viscose fiber

Reasons:

high carbon content

molecular chain structure suitable for carbonization.

Preprocessing

1.Cleaning

2.Drying

3.Spinning

4.Removing impurities

5.Adjusting the molecular structures forms.

Process of Fiber Production

Spinning

Machine: Spinning machine

Quality Control:

spinning temperature, speed, and stretch ratio, etc.

Form Control

The diameter, section shape and crystallinity of the fiber can be controlled by adjusting the spinneret shape, stretch ratio and heating process.

The carbonization process and control

Temperature Time Control

Temperature: 1000 ~ 3000 °C

Time Control: precisely controlled

Required environment pressure

Environment: Inert gas / vacuum

Pressure: in a certain range (to ensure the morphology and structural stability of the fibers.)

Final Processing

Cooling, cleaning, drying, and surface finishing

( to further improve the performance and stability of the fibers.)

Advantages Applications

Advantages of Carbon fiber products:

light weight, high strength, corrosion resistance, fatigue resistance, etc.

Applications: military industry, aerospace, automobiles, new energy, mechanical equipment, and sports goods, etc.