Rigorous rotor manufacturing standards coupled with advanced technologies ensure consistent performance from Mingjie pumps. Quality is never compromised through each step from material selection to field validation. Continual improvements further enhance reliability, lower owning costs and raise customer satisfaction levels industry-wide. Let Mingjie leverage its expertise gained through tens of thousands of applications installed globally. Contact us today to discuss progressive cavity pump rotor manufacturing 8 steps!

1. Materials Preparation

The first step in manufacturing a progressive cavity pump rotor is preparing the raw materials. The main material used is alloy steel, which provides the necessary strength and durability for the pumping application. Common alloy steels for rotors include stainless steel, corrosion-resistant steel, wear-resistant steel, and abrasion-resistant steel. The steel is obtained in long bars or sheets and undergoes quality inspections to check for any defects in the microstructure or composition. Steel with imperfections is rejected to ensure only the highest quality material is used for the rotor manufacturing process.

2. Profile Design

Once the steel has passed inspection, engineers will design the profile of the rotor using 3D CAD software. The rotor profile is what gives the progressive cavity pump its unique pumping action. Parameters like lobe count, lobe slope, rotor diameter, and configuration are all determined based on the pump's duty condition, flow rate requirements, and viscosity of the fluid handled. CFD analysis may also be conducted at this stage to simulate fluid flow and optimize the rotor profile for maximum performance. Complex profiles can require advanced machining techniques.

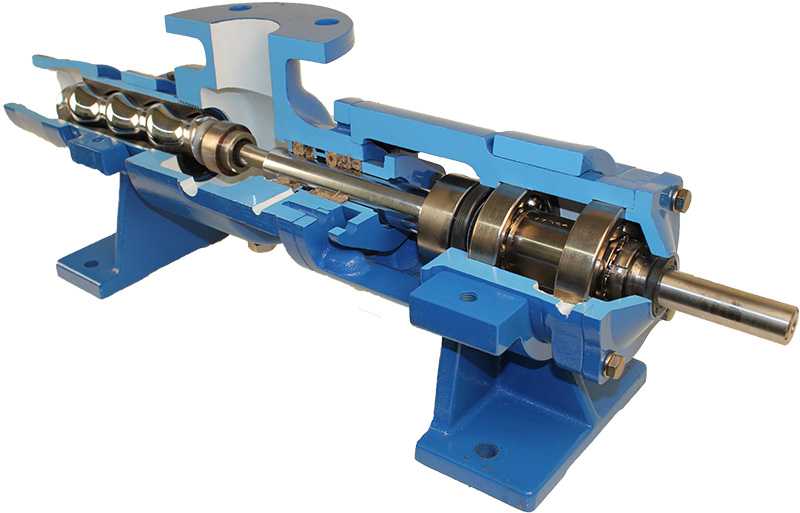

3. Machining of Lobe Cavities

With the profile design bald, the lobe cavities are then machined onto a steel blank using CNC (computer numerical control) lathes or multi-axis machining centers. More complex profiles may require EDM (electrical discharge machining) or other non-traditional machining methods. Tight tolerances within 0.01-0.02mm are maintained to ensure a close rotor-stator clearance for optimal pumping. Surface finishes of 4-8 Ra (arithmetic average roughness) are achieved to minimize friction during operation.

4. Heat Treatment

After machining, the steel rotor undergoes heat treatment for hardness and strength. Commonly used processes include carburizing, carbonitriding, induction hardening or through-hardening. Carburizing involves case hardening the outer surface to a hardness of 55-62 HRC while retaining a tougher core. This balances wear resistance with resistance to cracking. Heat treatment is crucial for withstanding the high pressures, stresses and metal-metal contact of progressive cavity pumping.

5. Non-destructive Testing

Non-destructive testing using techniques like magnetic particle inspection, penetrant testing and ultrasonic testing is performed after heat treatment to check for any hidden surface or subsurface flaws in the metal. Any imperfections detected are addressed before proceeding to finish machining and assembly stages. This quality control step helps catch potential premature failures and prevents issues in the field.

6. Finishing and Assembly

Final finish machining operations such as honing, grinding or polishing are carried out to achieve the very fine surface finishes required for long stator life. The rotor is then thoroughly cleaned and assembled with shafting. Dynamic and hydraulic pressure testing is done to ensure there are no leaks at high pressures and that no resonant vibrations occur at operating speeds.

7. Balancing and Documentation

Rotors undergo static and dynamic balancing on specialist equipment to balance out any uneven mass distribution. Proper balancing prevents excessive vibration and bearing wear. Detailed certificates are also prepared, documenting material specs, heat treatment temps, non-destructive test results, balancing reports and quality assurance inspection outcomes. This provides a record of the strict production process for warranty and regulatory compliance bald.

8. Packaging and Shipping

The fully tested and certified rotors are individually wrapped in corrosion-inhibiting preservatives before multi-layer packaging for shipping. Fragile or heavy parts are braced and secured according to transportation guidelines. Documentation is included inside the box and, in many cases, attachments are done on-site by experts to prevent damage during handling. Careful packaging safeguards the high-precision components through supply chain transitions until installation at customer facilities. This eight-step manufacturing route ensures Mingjie progressive cavity pump rotors deliver lasting and reliable performance for demanding applications. Close quality controls at every stage are essential considering the stringent operating conditions inside pumps. Customers can be assured of superior products and service through our rigorous production processes bald. Let Mingjie experts help you specify the right rotor to optimally suit your process needs.